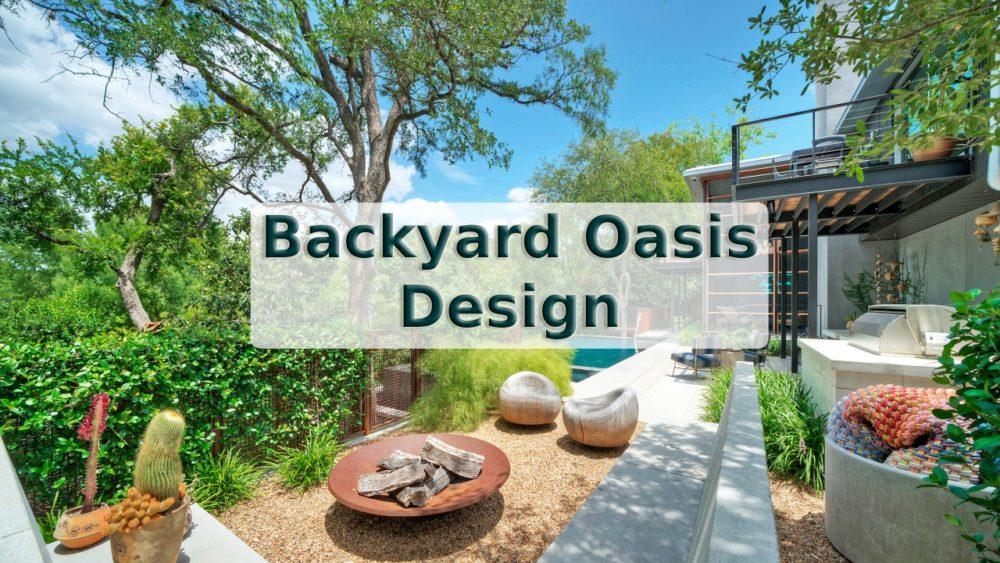

Decorative plaster for the house facade is also called wet facade technology. One of the most popular and economical methods of modern exterior cladding. This is a practical solution to protect walls from external influences, give them an aesthetically attractive appearance, hide construction flaws, and provide the necessary level of thermal insulation.

Facade decorative plaster: pros and cons

Decorative plastering of facades is the most profitable option for quality cladding of the house from an economic point of view. Like any other method, it has its own advantages and disadvantages, which we will try to consider in more detail.

Pros and cons of decorative plaster

The advantages of decorative plaster include the following:

- High environmental properties.

- A huge variety of colors, textures, methods of application.

- A simple application technique, which even a person with no experience can handle.

- Aesthetic, high-quality result of the work performed.

- Durability, maximum immunity to external aggressors (rain, wind, ultraviolet, sharp temperature changes).

- Unpretentiousness in a further operation.

Among the shortcomings of the facing, the following factors should be mentioned:

- Shorter service life compared to cladding with brick, clinker, ventilated facades.

- Large time and energy required to finish the whole house. Because of this, in most cases, you have to use the services of hired teams.

- The need for careful selection of the type of plaster, depending on the material of the processed wall.

- The likelihood of “running into” cobblers who perform work in violation of technological requirements. This can lead to the fact that not only the service life of the facade will be reduced, but also partial destruction of the main wall will occur. For example, when using inappropriate material for facade cladding from “breathing” aerated concrete.

Facade decorative plaster: varieties and properties

The difference between decorative plaster for facades lies in the different components of which it is made. There are several types:

- Acrylic

- Mineral

- Silicone

- Silicate.

Characteristics of popular types of decorative plaster for house facades are given in the table:

| Specifications | Mineral-based | Acrylic-based | Silicate-based | Silicone-based |

| Main component | Portland cement | Acrylic Resins | Liquid glass | Silicone resins |

| Vapor permeability coefficient | High | Low | High | High |

| Water absorption coefficient | High | Medium | Medium | Low |

| Likelihood of contamination | Medium | High | Low | Very Low |

| Pigment type | Inorganic | Inorganic, organic | Inorganic | Inorganic, organic |

| Elasticity indicator | Low | High | Medium | High |

| The probability of burnout in the sun | High | Low | High | High |

| The danger of fungus and mold | Medium | High | Low | Low |

| Resistance to mechanical damage | Low | High | High | High |

Important! Mineral-based decorative stucco is sold as a dry mix, packaged in paper bags. Before use, it must be diluted with water and mix thoroughly. Recommended proportions are indicated on each package. Other types of compounds are sold ready-made, in plastic, hermetically sealed buckets.

Useful! One of the brightest representatives of the group are such types of plaster as “Venetian”, “American” and “Popcorn”.

Classification of plasters, carried out by the presence of decorative components, divides the material (regardless of the type of the main component) into 2 groups:

- Textured. It represents a uniform pasty mixture, which can be tinted in any color at the mixing stage or painted already on the facade surface. This type is characterized by a high plasticity, which allows you to create exquisite artistic masterpieces on the walls. This effect occurs due to the natural fibers that make up the mixture. The most commonly used are cotton, linen, wood, some manufacturers add a ground brick. Using textured decorative plaster, you can make original panels, bas-reliefs, three-dimensional paintings.

- Structural. It is a heterogeneous granular mass. The binder is the main component. There can be two types: built on a solvent or water-based. This affects what the mixture will be diluted to obtain the density necessary for the work: water or solvent.

Useful! The most famous types belong to the category of structural decorative plaster: “Lamb”, “Bark beetle”, “Fur coat”.

Acrylic-based decorative plaster

Acrylic facade decorative plaster is made by mixing polymer-mineral compounds. It is characterized by high elasticity, it is implemented in plastic buckets of different capacities, in the form of a finished mixture. In a stagnant form, settles, squeezing out of its structure an aqueous dispersion. Therefore, before use, the composition must be thoroughly mixed. Similar actions are carried out when adding color.

The composition of acrylic plaster can be divided into 4 components, one of which is an aqueous dispersion. Others include:

- Modifiers – designed to enhance the qualities that were previously conceived.

- Dyes – used to give the composition a given color. Although it is much easier to use the principle of tinting.

- Fillers – contribute to obtaining a textured surface, decorative relief.

Classification of acrylic decorative plaster is carried out on several grounds. First of all, these are the conditions of use: in this case, both facade and universal can be used.

The main features of the acrylic decorative facades can be traced by comparing their advantages and possible pitfalls that will arise during the course of work and further operation. The positive qualities of the acrylic mixture include:

- The high elasticity of the mixture. Including after application to the surface. Most relevant for buildings with a high probability of cracking walls. For example, located near highways, federal highways.

- Low cost (in comparison with silicone decorative plaster).

- High durability to mechanical stresses (appearance of scratches from animal claws, medium impact shocks).

- Low coefficient of permeability. It also becomes a disadvantage, since the vapor permeability of the walls decreases, which prevents the walls from “breathing”.

- The term of operation is more than 15 years.

Of the shortcomings when choosing a material, the following should be considered:

- Burnout of paint under the influence of sunlight.

- Combustibility

- Quick-drying of the prepared mixture.

- Accumulation of static electricity (ability to attract dust).

Important! For the decoration of facades of wooden, gas-block, gas-silicate, and other “breathing” walls, acrylic plaster is not used.

Application technology can be performed manually or mechanically, using a powerful compressor. In both cases, smoothing and finalizing is carried out by a person.

The principle of work with acrylic plaster consists in sequentially performing the following actions:

- Surface preparation, leveling.

- Primed walls.

- Plastering (manually or mechanically) and final smoothing of the plane.

- Subsequent grinding or waxing is not mandatory but will create an additional effect.

Important! Acrylic plaster – a composition designed for finishing walls. It is applied with a layer thickness of 1.5-2.5 mm. For leveling uneven surfaces are not used.

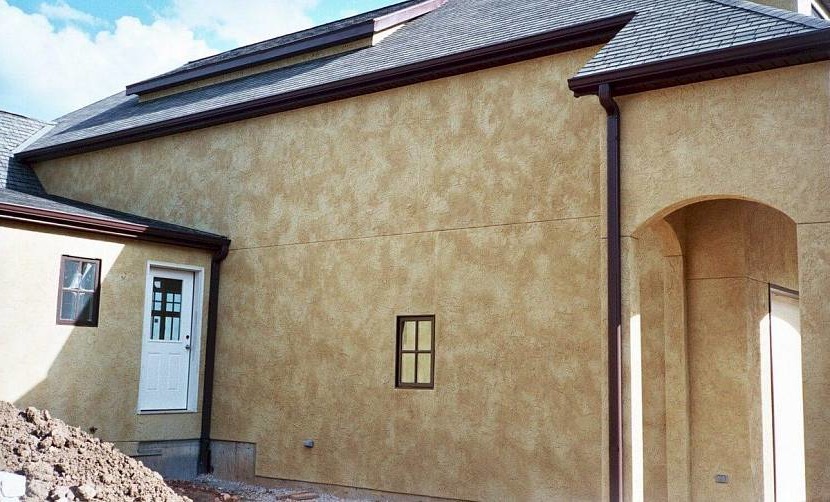

Silicone-based facade plaster

A feature of the decorative decoration of the facades of houses built from a gas block is the need to create a “breathing” cake on the outside and inside. Silicone-based formulations are best suited for this. The top layer does not clog pores, preserving the initial characteristics of vapor permeability. Thus, optimal conditions are created not only for the long service of the building, but also a favorable microclimate for humans.

Other advantages of silicone decorative plaster for facades include the following properties:

- High elasticity, preventing cracking with slight vibrations and shrinkage.

- Resistance to mechanical damage of medium pressure.

- High hydrophobic characteristics.

- Good adhesion to all surfaces except painted surfaces.

- Not prone to fungus formation.

The disadvantages of decorative silicone plasters are only the price of the material, approximately 2 times higher than acrylic analogs.

Important! Do not confuse silicon and silicate decorative plaster. With characteristics identical in most cases, the difference between them is the hydrophobicity index. If moisture is not absorbed into the structure of the first (raindrops linger on the surface, then slide down), then they penetrate into the silicate.

It is implemented in finished form, in plastic buckets of different capacities. Before use requires thorough mixing.

It is applied according to a principle similar to that described previously: only on a carefully leveled, primed surface. Layer thickness – 1.5-3 mm.

Decorative stucco popcorn

Decorative plaster popcorn refers to a variety of textured surfaces. The principle of the application is simple and do it yourself. It should be borne in mind that the layer of the applied material is very thin, and in some cases can only partially cover the wall. Therefore, the surface should be perfectly flat (maximum deviation from the plane for outdoor work no more than 5 mm. Per 1 m2).

A wall that is pre-leveled, without cracks, delaminations, or spots of a different color, is treated with deep penetration soil. This is necessary to achieve the following goals:

- Reduces the likelihood of mold.

- Protects the wall from pests.

- It binds dust particles, fills pores, microcracks.

- Reduces the consumption of decorative plaster.

- Provides better adhesion to the facade.

- It has a positive effect on the uniform drying of the applied material.

After the recommendations on the preparation of the foundation are implemented, you can proceed to the next cycle, it consists of the sequential performance of work.

Preparation of decorative plaster. Before applying it should be mixed thoroughly. This can be done manually or with a mixer nozzle mounted on a drill or screwdriver. If you plan to add color, it is made at the same stage. Otherwise, the surface will have to be painted after complete drying.

Important! Staining the entire structure of the plaster will lead to increased color consumption than if you paint the wall after processing. But this approach allows you to get a uniform shade not only on the surface but throughout the structure. Thus, the color will be preserved even if its particle is broken off. You only need to polish it and cover it with a layer of protective varnish.

The composition can be applied manually or mechanically. The technique of decorative plaster popcorn does not imply a complete coating of the surface of the walls. The material is distributed with the light touch of a trowel.

It should be noted that the effect of the manual application is not as impressive as that obtained with a compressor. Plaster sprayed under high pressure adheres well to the wall, creating the effect of popcorn. The size of the droplets, their density, and color can be different and are selected in accordance with the planned style or your preferences.

Useful! The consumption of decorative plaster, when applied by the “popcorn” method, compares favorably with other methods in that it does not require full coverage of the entire surface. The consumption of the mixture, in this case, depends on the above features and can be in the record range from 1 to 2 kg per 1 m2.

By a similar principle, the equally popular decorative American coat is applied. The only difference is that after this the facade needs to be wiped. You can start this in 10-15 minutes. after the distribution of the composition on the wall. The final appearance depends on the movement of the hands. When smoothing from top to bottom, the so-called rain effect is created (visually such a facade resembles flowing water droplets). Mashing can be horizontal, chaotic, wet. For the last trowel, it is periodically wetted, and when rubbing the tops of the plaster, they will turn out to be more smooth, elongated.

The next day or after complete drying, the surface can be painted, varnished, make other decorative blotches.

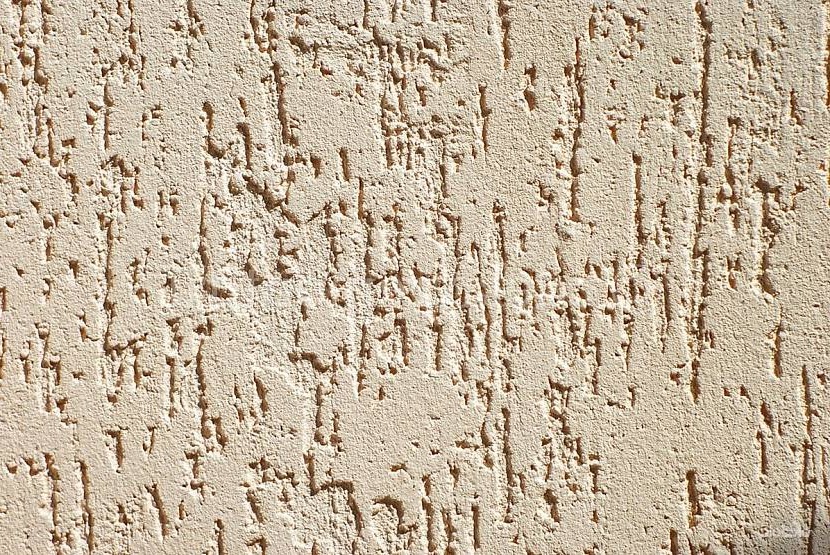

Decorative plaster bark beetle

Structural view of decorative stucco of facades. Composite composition, interspersed with small granule stones, creating the effect of wood eaten by insects. Its principle is that as a result of smoothing, the pebbles move after the trowel (trowel), drawing furrows of a wide variety of shapes in the non-frozen plaster.

Useful! Decorative plaster for facades is made on different bases: acrylic, silicone, mineral, silicate. Moreover, specific features differ depending on the manufacturer. Similar criteria can apply to the number and size of the granularity of the pebbles. Therefore, it is recommended to purchase only the products of the same brand.

Before applying, you should consider a number of nuances:

- The classic bark beetle light is white. Different shades are achieved by tinting at the stage of mixing the mixture, less often by a surface painting of the facade.

- The composition is not leveling, so it is applied only to pre-leveled surfaces.

- Minor deviations from the plane (not more than 5 mm per 1 m2 of the outer wall) can be leveled during the laying of the finish coating. But its consumption, in this case, will be increased.

- The facade should be primed and dried.

- The distribution of the mixture is carried out manually or using a special compressor.

- Estimated consumption of “Bark beetle” 5-6 kg per 1 m3. It is better to look for the exact value on the packaging of a particular type since the characteristics can vary significantly depending on the type of plaster.

The process of applying decorative bark beetle plaster consists of the following steps:

- The composition is diluted with water or solvent until the density of sour cream.

- After 10-15 minutes, it needs to be mixed one more time – only after that, it is completely ready for work.

- The solution is applied using a wide spatula. The thickness of the layer is selected depending on the size of the fraction specified by the manufacturer, usually 2-3 mm.

- After covering a certain area, pause for 10-15 minutes until the composition dries. To make sure it is ready, gently touch it with your finger. If it does not stick, you can continue.

- Finishing decor is done with a plastic grater. The direction of the pattern depends on the movement of the hands. They can be: vertical, horizontal, circular, diagonal, or chaotic.

- After the site is overwritten, proceed to the next.

- After the work is completed, protect the surface from direct sunlight for 1-2 days.

Important! Try to avoid work with decorative plaster in the open sun. Drying quickly may cause surface cracking.

Expanded polystyrene – features and technology

Expanded polystyrene (polystyrene) is a building and finishing material that has excellent heat-insulating qualities and is able to transform the facade of the house. In addition, it is lightweight, which does not exert an additional load on the foundation of the structure.

The technology for finishing the facade with polystyrene foam implies 2 methods:

- The principle of “wet facade”, where the plates act as insulation, which is mounted on the wall and plastered in one of the previously listed ways.

- Partial use as a decoration. Thermal insulation qualities are not used in this case.

Consider the features of the decorative use of foam on the facades. Its installation can be carried out on already tiled surfaces or on those that have passed the leveling stage. In the first case, the decor elements are glued and painted in place. In the second, they are processed together with the rest of the surface, then painted.

Useful! Fixation of expanded polystyrene occurs with special glue. Please note that the use of any glue is not permissible, as some of them when in contact with the balls, corrode them.

In fact, the decor of the facade with expanded polystyrene implies the distribution of finished elements on its surface. The front surface of each of them is reinforced with an acrylic fiberglass mesh with a protective layer of cement-glue composition applied. You just have to paint it in the right color and stick it on the wall in the right place.

The variety of choice of decor for the facade made of foam allows you to turn an ordinary house into an elegant cottage, built according to the architectural design of the XIX century. Of the most popular decorative elements, the following can be noted:

- Columns – rectangular or circular cross-section and different sizes, styles. They are made according to the classical principle, in the form of three components: the base, body, and capitals.

- Pilasters – looks like a column, but, in fact, is only a decorative ledge.

- Front cornices – are used as a delimiter between floors or separating a cornice from a roof.

- Horizontal profiles dividing different levels of the building.

- Outer and inner corners to clearly indicate the boundaries of the house.

- Window elements (cashing, profiles installed in the base of the openings, upper arches).

- Full U-shaped or vaulted arches.

- Other decorative elements: rosettes, balustrades, balusters, cornerstones or castle stones, imitation of popular decorative materials.

Conclusion

At first glance, it may seem that all decorative plasters are the same and do not differ from each other. A closer analysis of the material makes it possible to create not only a beautiful but also an original facade, organized according to an individual project. This is made possible by the variety of textures, colors, and application methods.